The Paint Product Stewardship Initiative Evaluation Committee presents the...

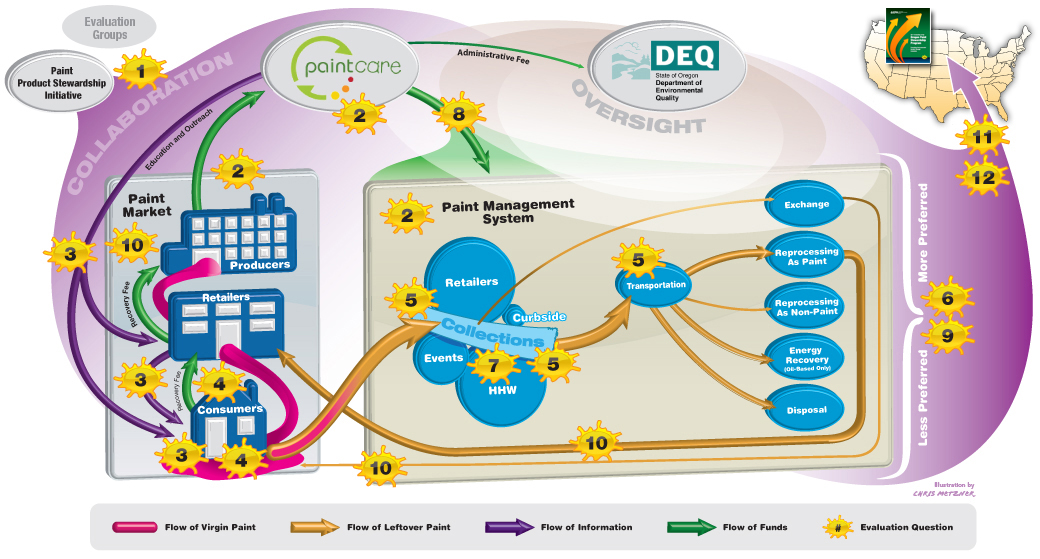

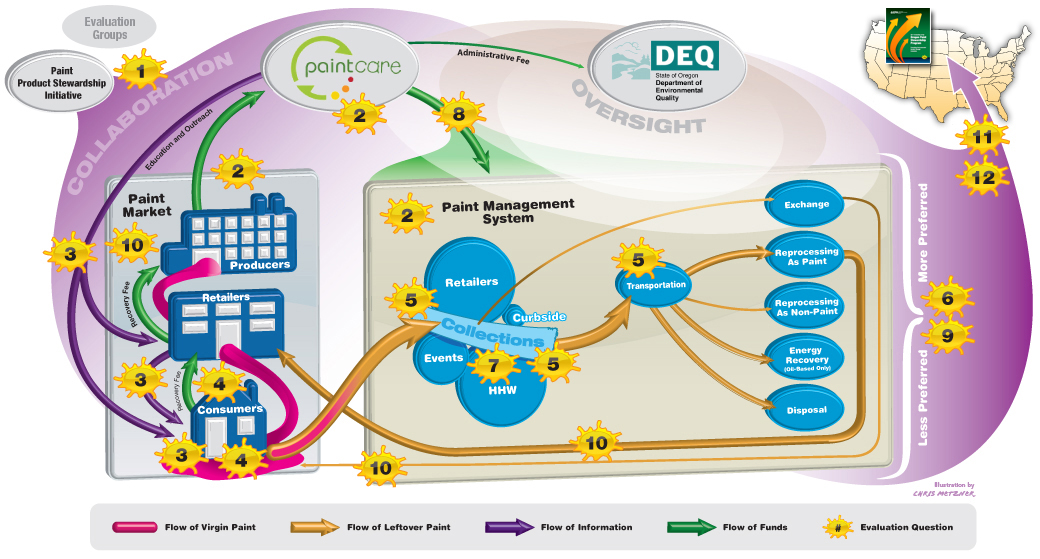

Explore the paint program and its evaluation committee's work by clicking various elements in the image below. |

|

|||||||

| Additional Materials | |||||||

| Title | Description | ||||||

| 1 | PaintCare Awareness Study | A powerpoint presentation of the PaintCare Awareness Study. | |||||

| 2 | Awareness Survey Response | A memo summarizing PaintCare and Bradshaw's response to the Committee's recommendations. | |||||

| 3 | PaintCare Awareness Survey of Oregon Homeowners - Report | The results of the August 2010 PaintCare Awareness Survey of Oregon Homeowners. | |||||

| 4 | PaintCare Awareness Survey of Oregon Homeowners - Results | The data collected from the August 2010 PaintCare Awareness Survey of Oregon Homeowners. | |||||

| 5 | PaintCare Awareness Survey of Oregon Residents | The results of the July 2011 PaintCare Awareness Survey of Oregon Residents. | |||||

| 6 | Method for Evaluating the Paint Product Stewardship Initiative’s Oregon Pilot Program | The latest draft version of the evaluation methodology document. | |||||

| 7 | Integrating Evaluation into Program Design | A paper on integrating evaluation into design of a project. | |||||

| 8 | Integrating Evaluation into The Oregon Pilot Program | A one page fact sheet that condenses key points from the full paper on integrating evaluation. | |||||

| 9 | Importance of Collecting Baseline Data for the Oregon Paint Stewardship Program | A memo describing the importance of collecting baseline data. | |||||

| 10 | Oregon Paint Pilot and Environmental Impact | A memo summarizing issues of measuring environmental impact related to the OR pilot project. | |||||

| 11 | Leftover Paint Oregon Pilot Project Evaluation: Prioritizing Evaluation Questions | A memo describing how the Committee prioritized the evaluation questions. | |||||

| 12 | Suggestions for Survey Sampling and Implementation | A memo describing the Evaluation Committee's recommendations for improving the draft Bradshaw survey instrument. | |||||

| 13 | Bradshaw Consumer Survey Instrument | The implemented version of the Bradshaw survey. (Also Appendix C of the Evaluation Methodology) | |||||

| 14 | Integrating Evaluation into the Design of the Minnesota Demonstration Project 2008 | A powerpoint presentation discussing evaluation and design in the context of the MN project. | |||||

| 15 | Introduction to Evaluating the Minnesota Demonstration Program 2007 | A powerpoint presentation providing an introduction to evaluation in the context of the MN project. | |||||

| 16 | The Measurement and Evaluation of the PPSI Oregon Pilot Program 2009 | A powerpoint presentation discussing measurement and evaluation in the context of the OR Pilot project. | |||||

| 17 | Data Visualization and Convenience Analysis of the Oregon Paint Management Pilot Program | Hedrick Strickland's master's project proposal addressing the convenience of the OR Pilot program through data visualization. | |||||

| 18 | Convenience Analysis of the Oregon Paint Management Pilot Program | A powerpoint presentation by Hedrick Strickland discussing her master’s thesis regarding the location convenience of the OR Pilot program collection facilities. | |||||

| 19 | Oregon Paint Stewardship Pilot Program – Interactive Figure Draft text, audio, or video scripts for figure components | The draft text of the pop-up boxes for the interactive figure, organized by diagram component. | |||||

| 20 | Graphic from the Iowa Department of Natural Resources | Describes the flow of paint and funds. | |||||

| 21 | Assessment of Collaboration of the Paint Product Stewardship Initiative (PPSI) Pilot Program | A powerpoint presentation PDF by Duke University graduate students discussing the assessment of collaboration of the OR Pilot program. |

|||||

| 22 | Assessment of Collaboration of the Paint Product Stewardship Initiative (PPSI) and Pilot Program | Duke University graduate student’s final report on collaboration. | |||||

| 23 | Interim Briefing 12-14-10 | Handout for Evaluation Committee Call, December 2010. | |||||

| 24 | OR Paint Pilot Project Evaluation Interim Briefing Call Recording | Recording of December 2010 Evaluation Committee phone call. | |||||

| 25 | Description of the Oregon Pilot Program Paint Stewardship Organization | Final report from the Georgia State University graduate students regarding the description of the OR Pilot program. | |||||

| 26 | Development and Prioritization of the Evaluation Questions | Description of the Evaluation Committee’s process to focus the scope of the evaluation. (Also Appendix A of the Evaluation Methodology) |

|||||

| 27 | PPSI Paint Demonstration Project Draft Work Plan | Document developed to inform the design of a paint management system in Minnesota. (Also Appendix B of the Evaluation Methodology) |

|||||

| 28 | Alternative Consumer Survey | Suggested Evaluation Team questions for a consumer survey. (Also Appendix D of the Evaluation Methodology) | |||||

| 29 | Analysis of Data Sources for Evaluation Questions 3 and 4 | Identification of potential data sources for answering evaluation questions related to consumers. (Also Appendix E of the Evaluation Methodology) |

|||||

| 30 | 2011-09-01 Oregon Paint Stewardship Pilot Program Annual Report | PaintCare's first annual report delivered to Oregon Department of Environmental Quality | |||||

| 31 | Paint Product Stewardship Pilot Plan Annual Report Appendix | Appendices from PaintCare's first annual report |

|||||

| 32 | PPSI Evaluation Committee Webinar 09-22-11 | Recording of the Evaluation Team's presentation of its evaluation of the OR pilot program. | |||||